Neck-in drum

Neck steel drum

The Neck-in Drum or Neck Drum is another type of open-head steel drum with global standards from the United Nations for use in packaging and transporting solid and liquid food products, hazardous and non-hazardous chemicals, beverages, agricultural products, and other materials.

The steel Neck-in Drum, due to its narrower opening compared to open-head steel drums, improves containerization in marine and land transport. The Neck-in Drum is produced and delivered by Beh Chelik Matin using fully automated modern lines with various thicknesses according to customer needs.

Features of the Neck-in Steel Drum:

It has a metal rim with high resistance

Easy to move and carry

Electrostatic powder painting system

7 layers Seamer

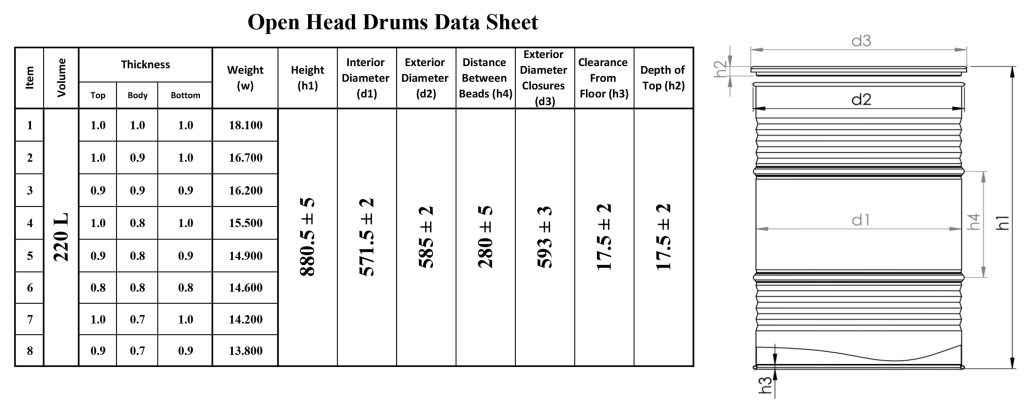

Technical specifications

Neck_In drum

Features and standards

Get to know the features and standards of Beh Chelik Matin Drum

Beh Chelik Matin standards

Global standards(15750)

National Standard of Iran No. (15661-2)

ISO 9001:2015 certification

Features of Beh Chelik Matin Neck-in Drum

Drum capacity according to customer order, including 220-liter and 230-liter drums

Drum color selection according to customer order from the standard color palette

Type of internal coating according to customer order

Custom design printing on the drum body and lid

Electrostatic powder painting system

Competitive pricing in domestic and international markets

High strength and durability

The strength and durability of the Neck steel drum are high due to the type of body sheet, design, and Electrostatic powder painting system .

Dedicated transportation fleet

All steel drums produced by Beh Chelik Matin are delivered to customers by the company's specialized trucks.

Optimized transportation of the Neck Drum

These drums fit perfectly next to each other, allowing for maximum storage in minimal space.

Inner coating of the Neck drum

The inner coating is one of the most important features of a drum, directly affecting the quality and safety of the materials inside. At Beh Chelik Matin, drums are manufactured with specific inner coatings based on customer needs.

The inner coating plays a crucial role in protecting the contents of the drum from corrosive agents, unwanted chemical reactions, and microorganism infiltration. This coating also helps maintain the physical and chemical properties of the products and prevents changes in their characteristics.

Beh Chelik Matin Neck drum color coating

Electrostatic powder painting system and liquid painting are two common methods in the industry for applying protective and aesthetic coating on different surfaces, each of which has its own specifications and applications. The drums painting stage in Beh Chelik Matin is considered as one of the most special stages of the competitive advantages of this company in the drum industry.

Electrostatic painting

Electrostatic power painting is used on all types of metal surfaces, including steel drums, due to its better adhesion. This method has a long life and resistance to scratching, engraving and separation from the surface, which is one of the strengths of this painting type compared to liquid painting.

For more information, you can read this article.

The color coating of Neck-in steel drums, like other steel drums, is very important in various industries, including chemical, pharmaceutical, and food and beverage industries. The importance of color coatings goes beyond aesthetics; these coatings include protection, regulatory compliance, and safety. Here, we examine the necessary standards for the color coating of Neck-In steel drums and highlight the legal requirements, performance criteria, application processes, and environmental considerations.

Sealing the drum lid with special plastisol

Beh Chelik Matin’s Neck-in drums are made from high-quality raw materials to resist corrosive chemicals. These drums must have a sturdy and sealed lid to prevent leakage. The plastisol around the Neck drum lid is one of the most prominent features of this drum.

Clasp and ring of the drum lid manufactured by Darposh Sazan Poya brand

The clasp and ring of drum lids are vital components in the design and production of industrial drums, playing an important role in maintaining the quality and safety of the drum’s contents. The specific features of clasps and rings, with different thicknesses, are used for packaging various materials.

Clasps and rings are generally made from durable metals such as steel and are installed on drum lids to ensure a tight and leak-resistant seal. These components are designed to withstand pressure and impact and prevent the entry of air and foreign materials into the drum.

Special thickness

The thickness of clasps and rings varies depending on the type of use and the drum’s contents. For example, drums used to transport hazardous chemicals or food products may require thicker rings to ensure the integrity of the contents against harsh transportation conditions.

Manufacturing standards

The production of clasps and rings is carried out according to international standards, and the thicknesses used for these components typically range from 0.7 mm to 1.25 mm. These standards ensure that the drums can withstand the necessary pressures for safe transportation. These standards are adhered to in all drums produced by the Beh Chelik Matin brand, including Neck-in drums. Clasps and rings are used in various types of drums, including metal and plastic drums. These components are designed to be sealed if necessary.

Ultimately, the clasps and rings of drum lids with special thickness play a key role in maintaining the safety and quality of the products inside the drums, and thus selecting the appropriate materials and thickness for their production is of great importance. Manufacturers must carefully consider customer needs and transportation conditions to ensure that the drums perform optimally.

Custom logo printing on the body and lid of the Neck-in drum

Beh Chelik Matin drum manufacturers can print the customer’s logo or custom design on the body and top lid of the drum based on the customer’s request. The Beh Chelik Matin execution team supervises all stages of stencil making and printing on the drum to ensure the highest quality printing process.

To learn about the benefits of custom brand printing, you can click the button below.

Applications of Neck-in Drums

Neck-in steel drums have various applications. Some of the applications of these drums are:

- Storage and transportation of food products, including perishable foods

- Storage and transportation of pharmaceuticals

- Storage and transportation of adhesives and resins

- Storage and transportation of industrial waste

- Maintenance and transportation of lubricants (solid lubricants such as grease)

Beh Chelik Matin steel drums are known in the domestic in foreign markets due to their high quality and competitive price. These drums are manufactured by using advanced technology and modern machineries, and more than 95% of their production is done automatically. Beh Chelik Matin drums are manufactured in different capacities, including 220 and 230 liter and possibility of single-color painting to three-color painting and silk printing on the side and top surface of drums.

These drums are suitable to use in various industries such as chemical, food, pharmaceutical, oil, resin, and all kinds of solvents and grease, and are used both in the domestic market and export of chemicals and industrial products.

This company operates with help of expertised staffs and modern equipment in accordance with the international and national standards of Iran and has been able to have a valuable position in improving the quality of drums as a final product.

To get more information about the price and desired features of your order, contact Beh Chelik Matin commercial team.

Open head steel drum

Tight head drum

Order registration

With more than a 20-year of experience, relying on its technical knowledge and expert staff, Beh Chelik Matin company has been able to manufacture high-quality steel drums to meet the needs of various industries. Compliance with all necessary standards to produce quality products is our main priority to meet all needs of customers. Respected customers can place an order by informing the sales experts about the weight or thickness of the drum sheet and the appearance specifications such as its color, required printing type and inner coating .

Some industries related to steel drums

Adhesive and resin industry

Steel drums with closed doors are very suitable for packaging materials such as glue and resin due to their resistant structure and variety of sizes. These drums, which are made of high quality steel or plastic, can protect resin and glue against chemical and physical factors and prevent changes in the quality of the materials inside them.

Food industry

Steel drums play a vital role in the food industry. Their sturdy and versatile construction makes them ideal for storing and transporting a variety of food products. However, ensuring the safety and quality of food products stored in these drums requires compliance with strict standards and regulations.

One of the most important topics in lubricants that affects the quality, safety and longevity of the product is packaging. Steel drums are the preferred choice for packaging lubricants due to their strength and protective properties. To ensure optimal performance, a steel drum for lubricant packaging must have certain characteristics.

pharmaceutical industry

Drug drums are a vital component in the pharmaceutical packaging industry. Their robust construction ensures the integrity and safety of contents during storage and transportation. These drums are often covered with a protective coating to prevent any possible reaction between the metal and the drug.