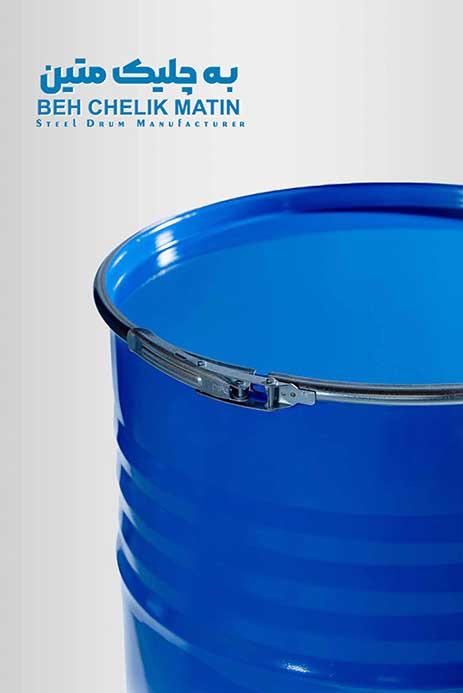

Lever lock ring of the drum lid

Essential standards for the Lever lock ring of the drum lid

Ensuring the security and integrity of these drums, especially when handling hazardous materials, is of utmost importance.One of the key components of this security is the Lever lock ring of the drum lid.Here, we will examine the necessary standards and best practices for the Lever lock ring of the steel drum lid, emphasizing the importance of complying with industrial regulations to ensure safety and reliability.

Legal frameworks and standards for the Lever lock ring of the drum lid

UN recommendations for the transport of hazardous materials

The United Nations provides comprehensive guidelines for the packaging and transport of hazardous materials.These recommendations include specifications for steel drum packaging to ensure they can withstand the stresses of transport without leaking or failing.Clamping mechanisms and rings must meet specific criteria to be approved for use with hazardous materials.

In the United States, the Department of Transportation has stringent regulations for the transport of hazardous materials. Steel drums must pass rigorous performance tests, including tests that evaluate the effectiveness of the clamping mechanisms and rings in maintaining the integrity of the drum under various conditions.Compliance with these standards is essential for legal transportation.

International Organization for Standardization (ISO) standards

– ISO sets global standards for the design and performance of steel drums, including ISO 15750, which outlines the requirements for drums used to transport hazardous materials.This standard includes specifications for the Lever lock ring to ensure a secure and reliable seal.

Key Components

1.Clamping Mechanisms

The clamping mechanism for securing the drum lid is one of the most critical sealing criteria in a steel drum.The steel drum ring must be designed to create a tight seal and prevent leakage and contamination. Key features of a high-quality clamping mechanism include:

Durability: Made from resistant materials like stainless steel to withstand corrosion and wear.

Ease of Use: Designed for easy operation while maintaining tightness.

2.Metal Ring

The metal ring holds the drum lid in place and creates even pressure around the lid’s perimeter.

Important aspects of packaging rings include:

Strength: Typically made from high-strength metal to withstand the forces encountered during handling and transport.

Even Pressure: Designed to apply even pressure around the drum lid to create a reliable seal.

3. Gaskets

Chemical Compatibility: Made from materials compatible with the drum’s contents to prevent degradation.

High Flexibility: Able to maintain shape and sealing capability across a wide range of temperatures and pressures.

Performance Testing

Leak Test: This test involves filling the drum with water or a similar liquid and pressurizing it to check for leaks.The Lever lock ring must maintain the seal without any signs of leakage.

Hydrostatic Pressure Test: The drum is subjected to internal pressure to simulate conditions it might encounter during transportation. The Lever lock ring must keep the lid secure without failure.

Drop Test: Drums are dropped from a specified height to assess their impact resistance.

The Lever lock ring must prevent the lid from detaching or leaking.

Stacking Test: Drums are stacked to a certain height and left for a specified period to check the structural integrity and reliability of the Lever lock ring under weight pressure.

Maintenance and Inspection Procedures

Best practices to ensure the performance of the Lever lock ring include:

1. Regular Inspections:

2.Proper Handling and Loading:

3.Training:

4. Use of Approved Components:

Beh Chelik Matin always uses the best raw materials to manufacture clamping mechanisms and rings, ensuring the safe transportation of drum contents for our valued customers.

Conclusion

Adhering to the required standards for the Lever lock ring of steel drum lids is essential to ensure the safety, integrity, and compliance of these containers.

By following the guidelines and best practices available, manufacturers and users can ensure that steel drums perform reliably under various conditions, protecting both contents and the environment.

Regular inspections and maintenance further enhance the longevity and effectiveness of these critical components, providing peace of mind to all stakeholders involved in the storage and transport of goods.

Order Registration

With more than a 20-year of experience, relying on its technical knowledge and expert staff, Beh Chelik Matin company has been able to manufacture high-quality steel drums to meet the needs of various industries. Compliance with all necessary standards to produce quality products is our main priority to meet all needs of customers. Respected customers can place an order by informing the sales experts about the weight or thickness of the drum sheet and the appearance specifications such as its color, required printing type and inner coating .

Share us.

Products manufactured by Beh Chelik Matin Steel Drum Manufacturing

Get familiar with metal barrel specifications and standards via Beh Chelik Matin company

Some industries related to steel drums

Drug drums are a vital component in the pharmaceutical packaging industry. Their robust construction ensures the integrity and safety of contents during storage and transportation. These drums are often covered with a protective coating to prevent any possible reaction between the metal and the drug.

Steel drums with closed doors are very suitable for packaging materials such as glue and resin due to their resistant structure and variety of sizes. These drums, which are made of high quality steel or plastic, can protect resin and glue against chemical and physical factors and prevent changes in the quality of the materials inside them.

Steel drums play a vital role in the food industry. Their sturdy and versatile construction makes them ideal for storing and transporting a variety of food products. However, ensuring the safety and quality of food products stored in these drums requires compliance with strict standards and regulations.

Industrial waste drums play an important role in the management and disposal of waste produced by various industries. Choosing the right type of drum, especially steel drums, ensures that safety, durability and compliance with legal standards are maintained. Here are the standards required for industrial waste drums…

One of the most important topics in lubricants that affects the quality, safety and longevity of the product is packaging. Steel drums are the preferred choice for packaging lubricants due to their strength and protective properties. To ensure optimal performance, a steel drum for lubricant packaging must have certain characteristics.