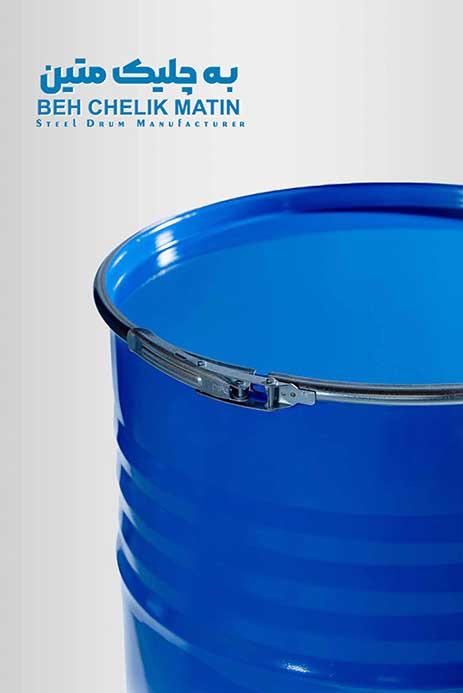

Food Steel Drum

Steel drum in food packaging

Steel drums play a significant role in the food industry. Their sturdy and multifunctional structure makes these drums ideal for storing and transporting various food products. However, ensuring the safety and quality of food products stored in these drums requires compliance with strict standards and regulations.

Types of steel drums used in the food industry

The most common types of steel drums used in the food industry are made of stainless steel and galvanized steel. Each type has specific applications based on its unique features:

Stainless steel drums: These drums are preferred due to their excellent corrosion resistance and ease of cleaning. They are ideal for storing liquids such as oils, syrups, and beverages, as well as dry goods like grains and powders.

Aluminum drums: Lighter than stainless steel, aluminum drums are often used for transporting food products where weight is a concern. They also have good corrosion resistance but are not as durable as stainless steel.

Galvanized steel drums: These drums are coated with a layer of zinc to prevent rusting. They are suitable for dry food products and some non-corrosive liquids. However, due to potential concerns about zinc contamination, they are used less for food storage compared to stainless steel.

Features and standards

Get familiar with metal barrel specifications and standards via Beh Chelik Matin company

Beh Chelik Matin standards

Global standards(15750)

National Standard of Iran No. (15661-2)

ISO 9001:2015 certification

Specification of Beh Chlik Matin steel drum

Drum capacity according to customer order, including 220-liter and 230-liter drums

Drum color selection according to customer order from the standard color palette

Type of internal coating according to customer order

Custom design printing on the drum body and lid

Electrostatic powder painting system

Competitive pricing in domestic and international markets

Required standards for food steel drums: Ensuring safety and quality

Food steel drums play a crucial role in the storage and transportation of various types of food. From grains to liquids, these drums must adhere to stringent standards to ensure food safety, quality, and regulatory compliance. This section examines the required standards for food steel drums and provides a comprehensive guide for manufacturers, suppliers, and consumers.

Material standards

The first consideration in food steel drum standards is the materials used. Materials must be non-reactive to prevent contamination. Common materials include:

High-density polyethylene (HDPE): Due to its strength and chemical resistance, HDPE is widely used for both solid and liquid food products.

Stainless steel: Due to its durability, corrosion resistance, and ease of cleaning, it is ideal for the long-term storage and transportation of liquids and acidic food products.

All materials must comply with regulations set by authorities such as the US Food and Drug Administration (FDA), requiring them to be non-toxic, non-absorbent, and resistant to degradation.

Essential note

In the Beh Chelik Matin collection, the produced drums have international standard certifications, but the health certifications for food and pharmaceutical materials are the responsibility of the consumer. Many food producers use aseptic bags for this purpose.

2. Food steel drum manufacturing standards

Manufacturing food drums must ensure durability and integrity of the contents. Key standards include:

Reinforced edges: Provide extra strength and prevent damage during handling and transportation.

Leak-proof seals: Essential for liquid storage drums to prevent leaks and contamination.

3. Hygiene standards

Maintaining hygiene in food storage is a critical and essential issue. Hygiene standards for food drums include:

Smooth interior surfaces: Facilitate easy cleaning and prevent residue buildup.

Sterilizable: Materials and design must allow for thorough cleaning and disinfection, whether through manual cleaning or automated systems.

Pest resistance: Drums should be designed to prevent the entry of pests such as rodents and insects, which can compromise food safety.

4. Food labeling and traceability standards

Pest resistance: Drums should be designed to prevent the entry of pests such as rodents and insects, which can compromise food safety. These standards include:

Clear identification: Drums should have clear, durable labels indicating the type of food, batch number, production date, and expiration date.

Compliance with legal requirements: Labels must comply with food safety legal requirements, including allergen information and storage instructions.

Tracking systems: Implementing tracking systems, such as barcodes or RFID tags, to monitor the movement and history of each drum.

5. Temperature control standards for food drums

For drums storing temperature-sensitive foods, specific standards must be met:

Insulation: Drums must be adequately insulated to maintain the required temperature range.

Compliance with cold chain requirements: For perishable items, drums must comply with cold chain logistics to ensure the safety and quality of food.

6. Legal compliance

Food drums must comply with international and national standards to ensure safety and quality. Key regulations include:

FDA (USA): Sets standards for materials, manufacturing, and labeling to ensure food safety.

European Food Safety Authority (EFSA): Provides guidelines and regulations for materials in contact with food in the European Union.

Codex Alimentarius: An international food standards body that provides guidelines on food safety, including packaging and storage.

Conclusion

Adhering to the necessary standards for food drums is essential to ensure the safety, quality, and integrity of food products. From material selection to manufacturing, hygiene, labeling, temperature control, and legal compliance, every aspect plays a vital role in maintaining food safety. Manufacturers and suppliers must be familiar with and comply with these standards to meet the stringent requirements of the food industry and protect consumer health.

Products manufactured by Beh Chelik Matin

Order registration

With more than a 20-year of experience, relying on its technical knowledge and expert staff, Beh Chelik Matin company has been able to manufacture high-quality steel drums to meet the needs of various industries. Compliance with all necessary standards to produce quality products is our main priority to meet all needs of customers. Respected customers can place an order by informing the sales experts about the weight or thickness of the drum sheet and the appearance specifications such as its color, required printing type and inner coating .

Share us.

Some industries related to steel drums

Drug drums are a vital component in the pharmaceutical packaging industry. Their robust construction ensures the integrity and safety of contents during storage and transportation. These drums are often covered with a protective coating to prevent any possible reaction between the metal and the drug.

Steel drums with closed doors are very suitable for packaging materials such as glue and resin due to their resistant structure and variety of sizes. These drums, which are made of high quality steel or plastic, can protect resin and glue against chemical and physical factors and prevent changes in the quality of the materials inside them.

Steel drums play a vital role in the food industry. Their sturdy and versatile construction makes them ideal for storing and transporting a variety of food products. However, ensuring the safety and quality of food products stored in these drums requires compliance with strict standards and regulations.

Industrial waste drums play an important role in the management and disposal of waste produced by various industries. Choosing the right type of drum, especially steel drums, ensures that safety, durability and compliance with legal standards are maintained. Here are the standards required for industrial waste drums…

One of the most important topics in lubricants that affects the quality, safety and longevity of the product is packaging. Steel drums are the preferred choice for packaging lubricants due to their strength and protective properties. To ensure optimal performance, a steel drum for lubricant packaging must have certain characteristics.